급성장하는 음식 배달 산업은 포장 제조업체에게 엄청난 주문량을 창출합니다. 이 고객은 이중 창고 시스템으로 다양한 식품용 용기의 빠른 회전율을 감당할 수 없다는 중대한 문제에 직면했습니다. 기존 장비로는 셔틀 시스템과 고밀도 보관 공간을 효율적으로 연결하지 못했습니다.

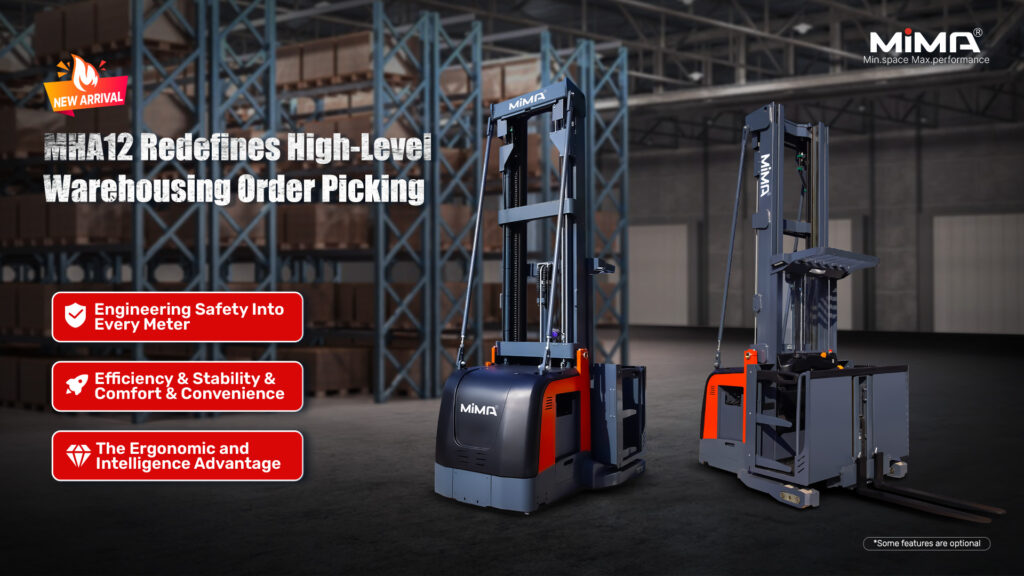

맞춤형 MiMA VNA 솔루션

MiMA는 이 초협소 통로 환경을 위해 특별히 정밀하게 일치하는 지게차 조합을 설계했습니다. MC16 3방향 팔레트 스태커와 MFZ16 리치 트럭은 고객의 이중 창고 시스템 간에 원활한 워크플로우를 만들었습니다.

네 가지 주요 이점이 제공됩니다:

MC16은 1.6미터 통로에서 작동하면서 10미터 높이까지 도달할 수 있어 설치 공간을 확장하지 않고도 수직 공간을 최대화할 수 있습니다. 마그네틱 내비게이션 시스템을 통해 사전 설정된 경로를 따라 자율적으로 이동할 수 있어 이동과 리프팅 작업을 동시에 수행하여 사이클 시간을 획기적으로 단축할 수 있습니다.

고급 십자선 타겟팅 및 HD 카메라 시스템은 고도의 작업 중에도 선명한 가시성을 제공하여 깨지기 쉬운 포장재를 손상시킬 수 있는 충돌 위험을 제거합니다.

소니의 솔루션은 기존 대안에 비해 뛰어난 ROI를 제공하여 공간 제약이 있는 환경에서도 최고의 운영 효율성을 유지하면서 장비 비용을 크게 절감할 수 있습니다.

MFZ16은 좁은 마스트 설계와 특허받은 안정화 시스템으로 속도와 정밀도를 높여 고층 적재 작업 시 하중 흔들림을 70%까지 줄여줍니다.

- 좁은 공간에서의 높은 기동성, 10m 리프트, 정밀한 적재 위치 지정.

- 특허받은 마스트 댐핑 및 전자기 제동으로 안정적인 고층 스태킹이 가능합니다.

- 지속 가능하고 유지보수가 적은 운영을 위한 에너지 절약 설계.

결과

이 MiMA 듀얼 지게차 접근 방식은 병목 현상이 발생하던 작업을 간소화된 시스템으로 전환했습니다. 이 고객은 이제 식품 안전 표준에 대한 타협 없이 더 많은 물량을 처리하여 올바른 장비 조합이 물리적 공간을 확장하지 않고도 창고 효율성을 혁신적으로 높일 수 있음을 입증했습니다.

때로는 가장 스마트한 솔루션은 더 큰 창고가 아니라 더 스마트한 장비일 수 있습니다.