Your forklift breaks down during peak hours. Production stops. Everyone waits. You need quick solutions that don’t require expert mechanics every time.

Master basic forklift troubleshooting with systematic daily checks, safety protocols, and simple repair techniques. Most common issues stem from battery problems, hydraulic leaks, or worn components that operators can identify and address quickly.

I learned this the hard way when our warehouse forklift died during a critical shipment deadline. The repair technician was hours away. That’s when I realized operators need basic troubleshooting skills to keep operations running smoothly.

What Are the Most Common Forklift Problems You’ll Face?

Equipment failures always happen at the worst times. Your productivity depends on quick problem identification. Smart operators spot issues before they become disasters.

Battery issues, hydraulic leaks, steering problems, and brake malfunctions account for 80% of forklift breakdowns. Regular inspection catches these problems early, preventing costly downtime and safety hazards.

Battery System Failures

Battery problems cause the most headaches in electric forklift operations. I’ve seen operators struggle with dead batteries, corroded connections, and electrolyte issues that could be prevented with proper maintenance.

Check electrolyte levels weekly. The liquid should sit 10-15mm above the pole plates. Low levels damage battery cells permanently. Distilled water works for refills. Never add acid unless a technician recommends it.

Clean battery terminals monthly. Corrosion creates resistance that reduces power and shortens battery life. Use baking soda solution for cleaning. Wear safety gear. Acid burns cause serious injuries.

Monitor charging cycles carefully. Batteries need 8 hours of charging after each shift. Partial charges reduce battery capacity over time. The charging area needs good ventilation. Hydrogen gas creates explosion risks.

Hydraulic System Issues

Hydraulic problems show up as slow lifting, jerky movements, or complete system failure. Oil leaks create safety hazards and environmental concerns. Most issues trace back to contaminated fluid or worn seals.

Check hydraulic oil levels daily. Low oil causes pump damage and system overheating. The oil should look clean and flow smoothly. Dark or thick oil needs immediate replacement. Metal particles indicate internal wear.

Inspect all hydraulic lines for leaks. Small drips become major problems quickly. High-pressure systems can inject oil into skin. Never touch suspected leak areas with bare hands. Use cardboard to check for spray patterns.

| Component | Check Frequency | Warning Signs |

|---|---|---|

| Oil Level | Daily | Low fluid, discoloration |

| Hoses | Weekly | Cracks, bulges, leaks |

| Cylinders | Monthly | Slow operation, drift |

| Filters | 240 hours | Pressure drops, noise |

How Do You Perform Effective Daily Safety Inspections?

Daily inspections prevent 90% of equipment failures. Most operators rush through checks or skip them completely. This creates dangerous situations and expensive repairs that proper inspection would catch early.

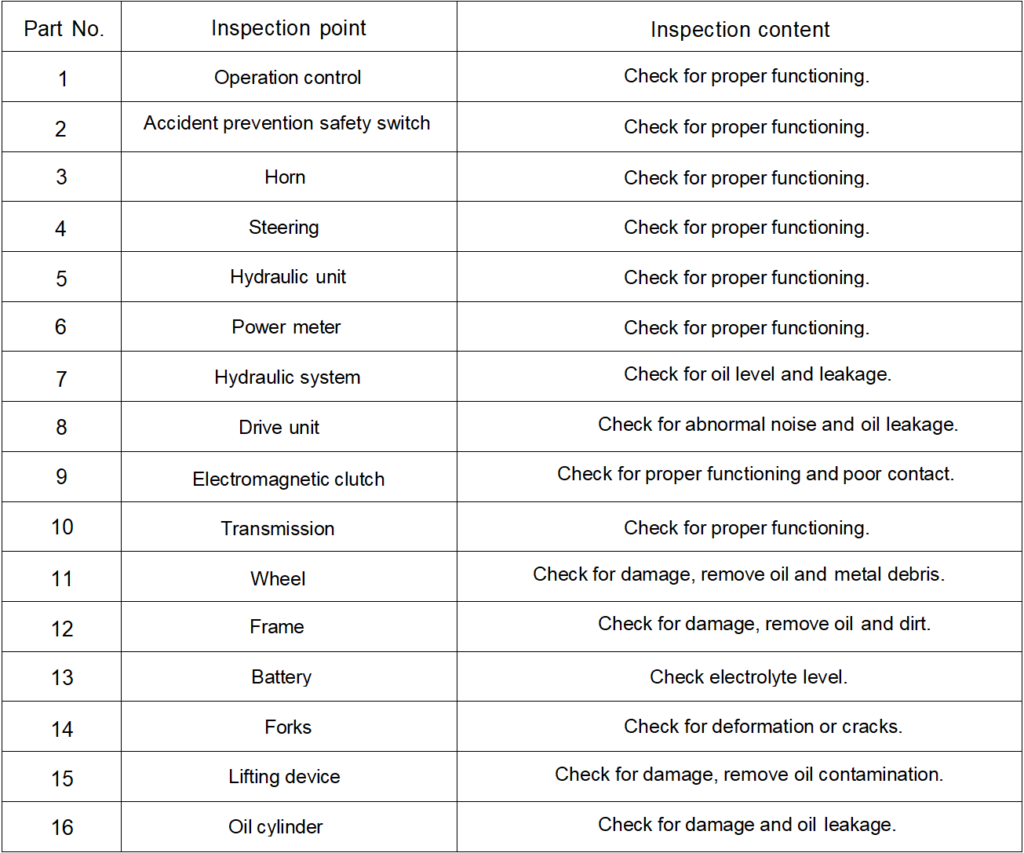

Follow a systematic 15-point inspection covering operation controls, safety systems, steering, hydraulics, wheels, battery, and forks. Document problems immediately and remove unsafe equipment from service until repairs are completed.

Pre-Operation Checklist System

Start every shift with the same inspection routine. Consistency catches developing problems before they cause failures. I use a printed checklist that covers all critical systems in logical order.

Check operation controls first. Test the steering, acceleration, and braking response. Horn and warning lights must work properly. Safety switches should engage correctly when activated.

Inspect the mast and forks for damage. Look for cracks, bent components, or excessive wear. Fork positioning should be smooth and precise. Any hesitation indicates hydraulic problems that need attention.

Examine wheels and tires carefully. Remove debris that affects rolling. Check for cuts, excessive wear, or loose mounting bolts. Drive wheels carry heavy loads and fail suddenly when worn.

The battery compartment needs daily attention. Check electrolyte levels and terminal connections. Look for acid spills or corrosion damage. Clean surfaces prevent electrical problems and extend component life.

Documentation and Reporting Procedures

Write down everything you find during inspections. Small problems become big failures when ignored. Maintenance teams need accurate information to plan repairs and order parts effectively.

Use simple problem descriptions that mechanics understand. “Steering feels loose” helps more than “something’s wrong with the front end.” Include specific symptoms, when they occur, and how severe they seem.

Take photos of damage or unusual wear patterns. Visual documentation helps parts suppliers and repair technicians understand problems quickly. Modern phones make this easy and fast.

Report safety issues immediately. Never operate equipment with brake problems, steering issues, or structural damage. Production delays cost less than accident injuries and liability claims.

What Basic Repairs Can Operators Handle Safely?

Operators can perform simple maintenance tasks that don’t require special tools or technical training. Basic cleaning, lubrication, and component replacement keeps equipment running between professional service intervals.

Wheel cleaning, battery maintenance, hydraulic oil checks, and minor adjustments fall within operator capabilities. Always disconnect power before starting work and follow lockout procedures to prevent accidental equipment activation.

Battery Maintenance Procedures

Battery care extends equipment life and prevents sudden failures. Most operators can handle routine maintenance safely with proper training and safety equipment.

Clean battery terminals monthly using protective gear. Disconnect power first. Remove corrosion with baking soda solution and wire brushes. Coat terminals with petroleum jelly to prevent future corrosion.

Check electrolyte levels weekly during charging cycles. Add distilled water to maintain proper levels. Never overfill cells. Excess electrolyte spills during charging and creates corrosion problems.

Equalization charging requires special procedures every three months. First complete normal charging. Wait one hour. Then charge at reduced current until batteries gas vigorously. This balances cell voltages and extends battery life.

Keep charging areas clean and well-ventilated. Hydrogen gas accumulates during charging and creates explosion risks. No smoking or open flames near batteries. Install proper ventilation systems in charging rooms.

Cleaning and Lubrication Tasks

Regular cleaning prevents premature wear and identifies developing problems. Oil and debris hide damage that leads to expensive repairs. Clean equipment runs better and lasts longer.

Remove wheel debris daily. Strings, wire, and plastic wrap damage bearings and create safety hazards. Clean wheels roll easier and reduce motor strain. Check mounting bolts while cleaning.

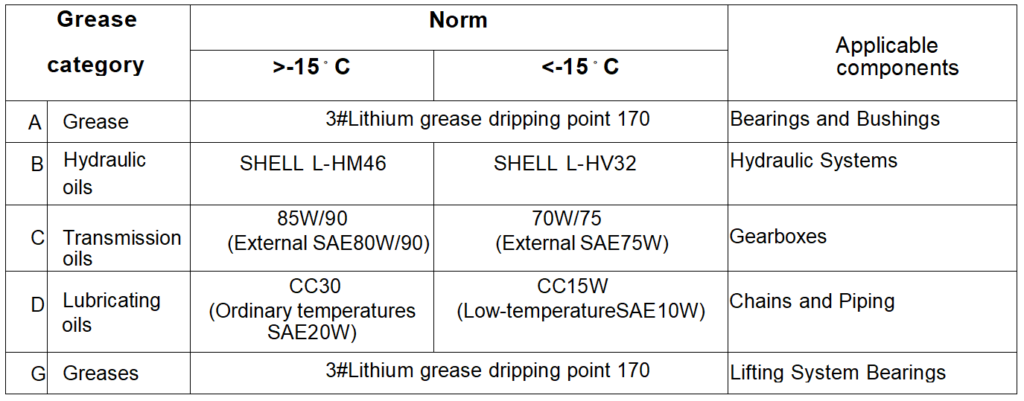

Lubricate grease fittings according to manufacturer schedules. Use specified grease types for different components. Over-lubrication attracts dirt and causes seal damage. Follow the lubrication chart exactly.

Clean electrical components with compressed air only. Water damages circuits and creates short circuit risks. Remove dust from motor cooling fans regularly. Blocked airflow causes overheating and motor failure.

| Maintenance Task | Frequency | Safety Requirements |

|---|---|---|

| Battery cleaning | Weekly | Protective gear, ventilation |

| Wheel debris removal | Daily | None |

| Grease fitting service | 500 hours | Clean grease gun |

| Motor cleaning | Monthly | Compressed air only |

Basic troubleshooting skills keep your forklift running when problems occur. Daily inspections catch issues early. Simple maintenance prevents expensive repairs and dangerous failures that shut down operations.