If you’re handling long materials like steel pipes, aluminum profiles, rebar, or even long wooden panels, you’ve probably run into the same question many others have.

“How do I move this stuff around safely and easily, especially in tight spaces?”

You may have tried standard forklifts. But they don’t move sideways. They need a wide aisle. And they struggle when loads get long and awkward.

That’s where the electric multi-directional forklift takes its position. Also called side loaders, they are designed to handle these warehousing situations. An electric multi-directional forklift is a specialized piece of material handling equipment that can move loads in multiple directions, including forward, backward, sideways, 360° in-situ rotation, and right-angle turning, without needing to turn the entire truck.

Then, what are electric multi-directional forklifts anyway? I will explain it clearly in this article.

1 What does “electric multi-directional” even mean?

It’s actually pretty simple.

Electric means it runs on a battery, not diesel or gas. It’s clean, quiet, and great for indoor use where emissions and noise are a concern.

Multi-directional means it can drive forward, backward, sideways, and even diagonally. Most models can rotate 360 degrees in place. This is contributed to by their wheels being able to move and turn independently.

In short, it goes wherever you need it to, perfectly suitable for narrow warehouse aisles.

2 How is it different from a regular forklift?

A regular forklift only goes forward and backward. Turning takes space. A lot of it.

But a multi-directional forklift can move sideways, just like a crab. So, when you have a 10-meter-long load, you don’t have to make awkward turns. You just slide sideways and go.

There is more that a multi-directional forklift can do:

- Rotate in tight spots

- Operate in aisles as narrow as 2 meters

- Lift heavy loads to high racks (8 meters and even more)

- Handle long, bulky materials (2-20 meters) with ease

This is not just a forklift. It’s a space-saving, time-saving, long-material-handling machine.

3 Who really needs this kind of forklift?

If your business deals with long or bulky materials and the aisle width is limited, or, simply, you want a tailored VNA solution for your long loads, side loaders, or multi-directional forklift, is made for you.

That includes industries like steel processing, aluminum extrusion, wood and timber, rebar manufacturing, and logistics with oversized cargo.

Even if you’re a distributor or dealer, it’s a smart product to recommend when a client says, “My warehouse is small, but my materials are long.”

4 Why electric? What’s the advantage?

Electric forklifts have a lot going for them. For starters, they’re super quiet, which makes them perfect for indoor use. They’re also clean—no exhaust fumes—so your team’s breathing easier.

And when it comes to cost, charging is usually way cheaper than fueling up. On top of that, electric models are low maintenance. Fewer moving parts mean fewer things to break.

With today’s battery tech, many electric forklifts can work a full shift on a single charge. Some offer fast charging or even battery swapping, depending on the model.

5 Is it easy to operate?

Yes—very.

Most electric multi-directional forklifts are designed with the operator in mind. Features often include:

- Simple joystick controls

- Digital displays

- Safety sensors for stability

- Comfortable cabins with 360° visibility

Some even support one-button switching between forward and sideways movement. With a little training, any forklift driver can handle it.

6 What are the key features I should look for?

Good question. Here are some things to keep in mind:

First, make sure it can move around comfortably in your aisle space. Then think about the size and weight of the loads you’re handling, can it lift what you need it to? Also, consider how high it can reach—can it get to your top shelves? A tighter turning radius is always a plus.

And don’t forget battery life; long runtime or fast charging can make a big difference. Safety features like anti-tip systems, speed limiters, and overload protection are also definitely worth having.

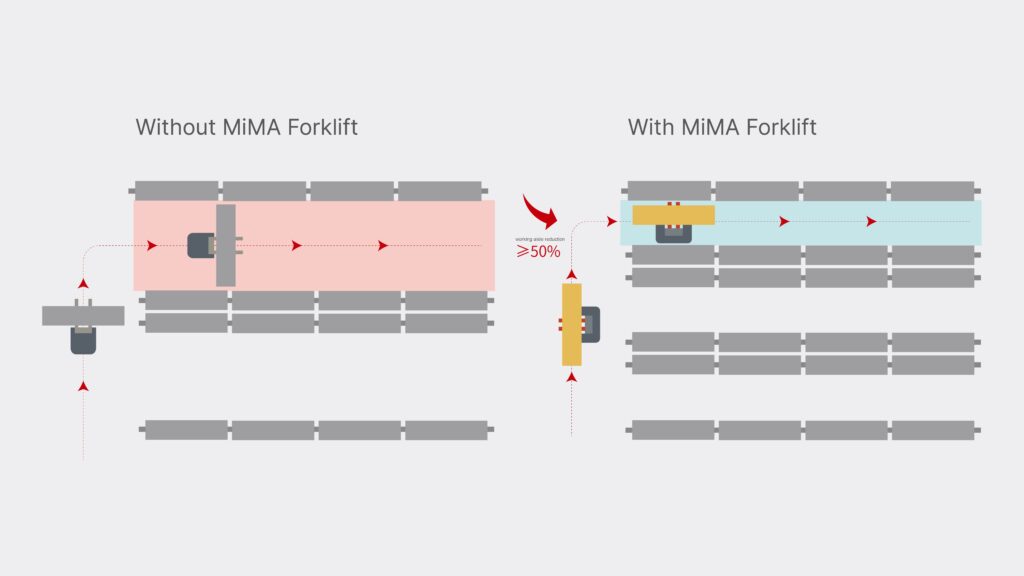

7 How much space can it save?

A lot.

In traditional setups, you might need 3-4 meters of aisle space to turn a standard forklift with long material.

With a multi-directional forklift, you can get by with just 2 meters, depending on the model and load size. That means more storage space and more efficiency in the same area.

8 Is it expensive?

Not necessarily.

Yes, the initial price is higher than a standard forklift. But don’t just look at the price tag.

Think about the total cost of ownership:

- Less damage to products and racking

- Fewer forklifts needed

- Faster operations

- More storage space = lower warehouse rent

- Less downtime and maintenance

In the long run, it often pays for itself.

9 So… which brand should I choose?

There are many options out there—European brands, North American manufacturers, and now some very competitive Asian brands with good quality and lower cost.

Some key things to look for:

- Strong customer support

- Warranty and after-sales service

- Availability of spare parts

- Customization options (load size, battery type, cabin type)

We have covered brand recommendations in another article: Top 5 Multi-Directional Forklift Manufacturers

But the main point is: don’t just buy the cheapest—buy the most suitable.

The electric multi-directional forklift is not just a piece of equipment. It’s a solution to a common problem: moving long loads in tight spaces or VNA—safely, quickly, and efficiently.

Whether you’re a factory owner, a warehouse manager, or a distributor looking to serve your clients better, this forklift could be the upgrade you’ve been looking for.

Still have questions? Feel free to reach out. We’re happy to help you choose the right one.