Operational Challenges

❶ Limited warehouse capacity

Due to an outdated layout and underutilized vertical space, the client’s warehouse capacity could no longer keep up with growing production volumes. This was creating serious bottlenecks in logistics and order fulfillment.

❷ Low handling efficiency for multi-SKU orders

The complexity of handling diverse product types led to frequent forklift changes and inefficient picking operations, slowing down deliveries and increasing labor costs.

❸ Sensitive material handling risks

Some electronic components are highly sensitive to vibration and temperature, making safe, stable storage and handling critical to prevent quality issues and safety hazards.

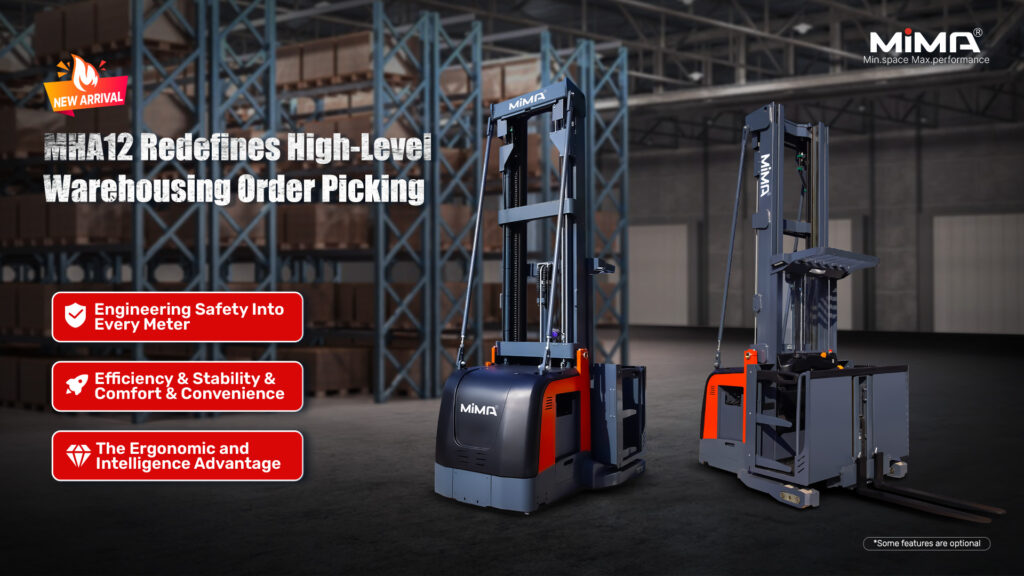

Tailored Solution from MiMA

To address these challenges, MiMA’s engineering team proposed a Very Narrow Aisle (VNA) high-density storage solution, featuring the MCC16 Man-up Turret Truck. This solution significantly improved storage efficiency, picking accuracy, and the overall safety of material handling.

✅ High-Density Storage Upgrade

The MCC16 supports a lifting height of up to 15.8 meters and a rated load of 1.6 tons. Operating in aisles as narrow as 1.65 meters, it maximizes use of both vertical and horizontal warehouse space. This helped the customer expand storage capacity without expanding the warehouse footprint.

✅ Faster, More Accurate Picking

With its man-up design and clear operator visibility, the MCC16 enables faster and more precise picking, even for complex, multi-SKU orders. Its ability to drive and lift simultaneously reduces the need for frequent forklift changes, saving time and significantly shortening the order fulfillment cycle.

✅ Safe Transport for Sensitive Materials

The customer also chose the magnetic navigation system, allowing the truck to automatically follow pre-set paths. This not only reduces operator workload but also enhances driving stability. Combined with large load-bearing wheels and all-wheel electromagnetic braking, the MCC16 offers smooth, controlled movement—perfect for handling delicate components with strict safety requirements.

Customer Gains

With MiMA’s MCC16 solution, the customer successfully transformed their warehouse operations, achieving:

- 30%+ increase in storage density

- 40%+ improvement in order processing speed

- Safer handling of sensitive materials with fewer product losses

MiMA remains committed to delivering smarter, safer, and more efficient intralogistics solutions for future-focused manufacturers.