A global precision instrument manufacturer faced critical constraints: storage capacity hitting limits, inefficient order picking, and material flow bottlenecks. Their warehouse needed radical transformation, without expanding footprint.

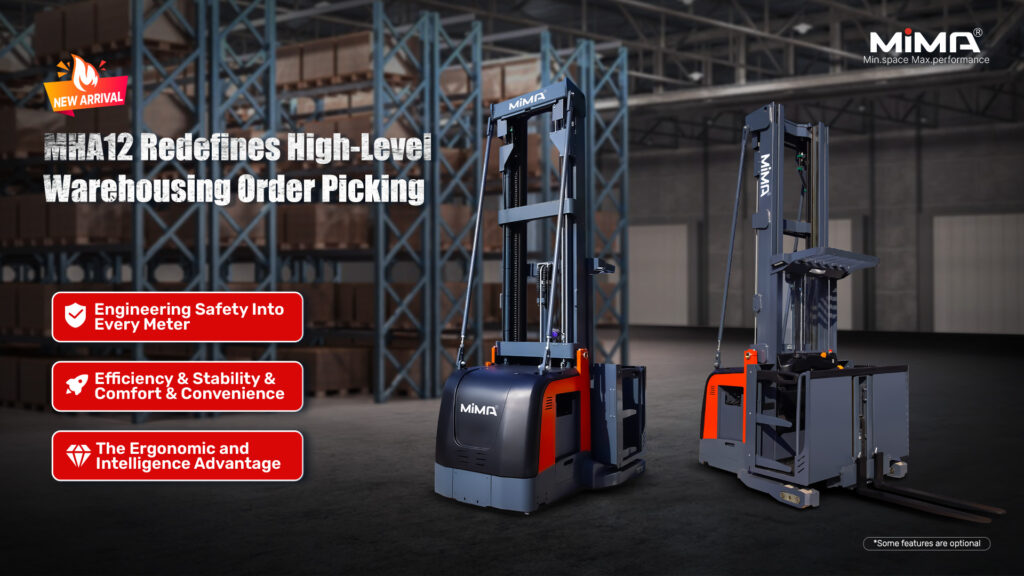

MiMA delivered a breakthrough: the MC12 3-way pallet stacker, engineered for ultra-narrow aisle performance and vertical optimization.

Key Challenges

- Storage capacity couldn’t match growing material and product volumes

- Frequent equipment switching slowed order picking

- Inbound/outbound logistics lacked speed and synchronization

MiMA Custom Solution: Stand-on 3-way pallet stacker MC12

🔹 Aisles Reduced, Storage Multiplied

🔹 Reach Higher, Store Deeper

Custom 6000mm lift height maximizes vertical space utilization, significantly increasing storage positions within existing area.

🔹 Smart Operation, Precision Handling

Laser guidance ensures straight-line travel in aisles. High-precision mast and camera system guarantee safe, accurate high-level stacking.

🔹 Unified Workflow

Man-up design enables operators to perform high-level stacking and ground-level picking in single operation, eliminating equipment switching.

The Result

50% more storage capacity, faster order processing, and streamlined material flow, all within the same warehouse footprint.

Where others see limits, MiMA engineers possibilities. MiMA doesn’t just sell forklifts, we engineer warehouse transformation. Beyond storage, it’s a new logic for space.